iQpump® Controller 5 thru 500 Horsepower

|

|

The iQpump® controller was designed with the pump service operators and pump system owners in mind. iQpump® offers ease of setup and comprehensive pump and motor protection features. The integrated pump specific software and setup parameters, allow the operator to setup specific control values for a wide rantge of applications.

The iQpump® controller will automatically adjust pump operating conditions conditions, as the process variables change while still maintaining optimum pump performance and protection. iQpump® can also replace phase converters when converting from a single phase to a three phase pump motor.

Concept and Control Methods

Designed with the pump service operators and pump system owners in mind, iQpump® offers ease of setup and comprehensive pump and motor protection features.

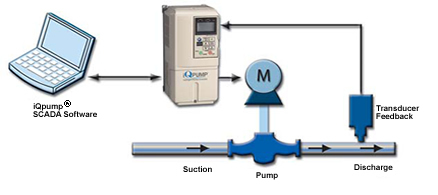

Simplex System Overview

Easy Installation and Set Up Easy Installation and Set Up

- Wire

- iQpump® Control

- Connect pipe to pump

- Set Pressure (PSI) Reference

- Calibrate Feedback Level (PSI)

- Start iQpump® control

Triplex System Overview Triplex System Overview

- Automatically starts and stops Lead/Lag pumps on demand.

- Automatically turns off pump when demand is reduced.

|

|

| Benefits |

- Improved Process Control... by matching pump output flow or pressure directly to the proceess requirements, small variations in the process can be corrected more rapidly.

- Improved System Reliability...any reduction in speed achieved major benefits in reducing pump wear, particularly in bearings and seals.

- Reduce Total System Cost...system costs are lowered by eliminating sensors, jockey pumps, restriction valves as well as reducing cable and tank sizing.

- Energy Savings...savings of 20 to 50% can be achieved, depending on application, by adjusting pump speed to match a lower flow/pressure, iQpump® will reduce the demand for energy.

|

- Ease of Installation and Setup...iQpump® uses pump terminology on all setup parameters and monitors. Also included is a "Pump Quick Setup" menu.

- Eliminate Complex Control Panels... many of the electro mechnical controls can be eliminated, reducing the maintenance that these panels require.

- Reduce Mechanical Stress and Damage... soft-start and soft-stop capabilities eliminates pressure surges and water hammer.

- Cooler Running Pump Motor...soft start eliminates inrush current, dramatically increasing winding insulation live.

|

-

Pump Specific Operator Keypad...onboard LCD English read out reduces field start up and trouble shooting time, with intuitive pump related terminology. Progarammable pump process set points are adjusted using "True Engineering Units" (PSI, GPM , Flow, etc.) The iQpump® provides real time alarms, status and operating conditions in easy to read format.

|

|

|

|

Software Features

|

The iQpump® integrated pump specific software allows the operator to quickly set up specific control values for a wide rante of applications. The controller then automatically adjusts pump operation as the system variables change while still maintaining optimum pump performance and protection.

|

- Programmable Set Point & Scaling... 12 different plain text engineering units are avilable, including PSI and GPM

- Control Pressure, Start Level & Start Time... flexibility to start the pump at different feedback levels or use the integrated timer to eliminate cycling.

- Sleep Mode Minimum Flow Protection... protects and shuts down the pump at low speeds or in low flow conditions.

- No Flow Detection... separate from Sleep Mode, this detects changes in motor RPM relative to sudden changes in pressure or flow; protecting against broken pipe, excessive well drawdown or run-dry conditions.

- Pre-Charge Control... this programmable feature eliminates water hammer and extends system life by gradually filling a pipe line before normal full pressure and flow operation. Motor speed can be controlled with a system timer, level or pressure control device to indicate when normal operation may begin.

- Thrust Bearing Control... protects the bearings of submersible motors by ensuring start up speeds and times meet manufacturer's recommendations.

- Automatic System Restart... programmable timers allow the iQpump® to automaticalloy restart the system in Auto Mode for faults relating to brown out's, no power, power spikes, and dry well.

- Friction Loss Compensation... automatically adjusts to overcome increased friction loss due to increased flows.

- Low & High Pressure Feedback Detection... iQpump® continously monitors the system feedback device to provide a warning alarm or fault based on programmed level.

- Multi-Pump Operations... iQpump® systems can be set up to automatically control two or more pumps to meet specific demands.

- Multiplex Automatic Stabilization... iQpump® automatically balances multi-pump systems to stabilize performance and reduce cycling.

|

- Pump Fault and Alarms... iQpump® provides a comprehensive set of pump related alarms and faults. Faults are displayed on the keypad in clear text to eliminate confusion.

- Over Cycling

- No Flow

- Loss of Prime

- Transducer Loss

- Over Torque

- Low & High Pressure Feedback detection

- Pump Over Cycling

- Dry Well

- Motor Protection... iQpump® protects the motor by monitoring

- Output Phase Loss

- Ground Fault

- Motor Overload

- Motor Over Tmperature

- Broken Shaft

- iQpump® Drive Protection...

- Over Voltage

- Input Phase Loss

- Under Voltage

- Phase Imbalance

- Short Circuit

- Transducer Loss Protection... iQpump® monitors the feedback device voltage or current levels to determine if the transducer has failed.

|

| |

|

|

|